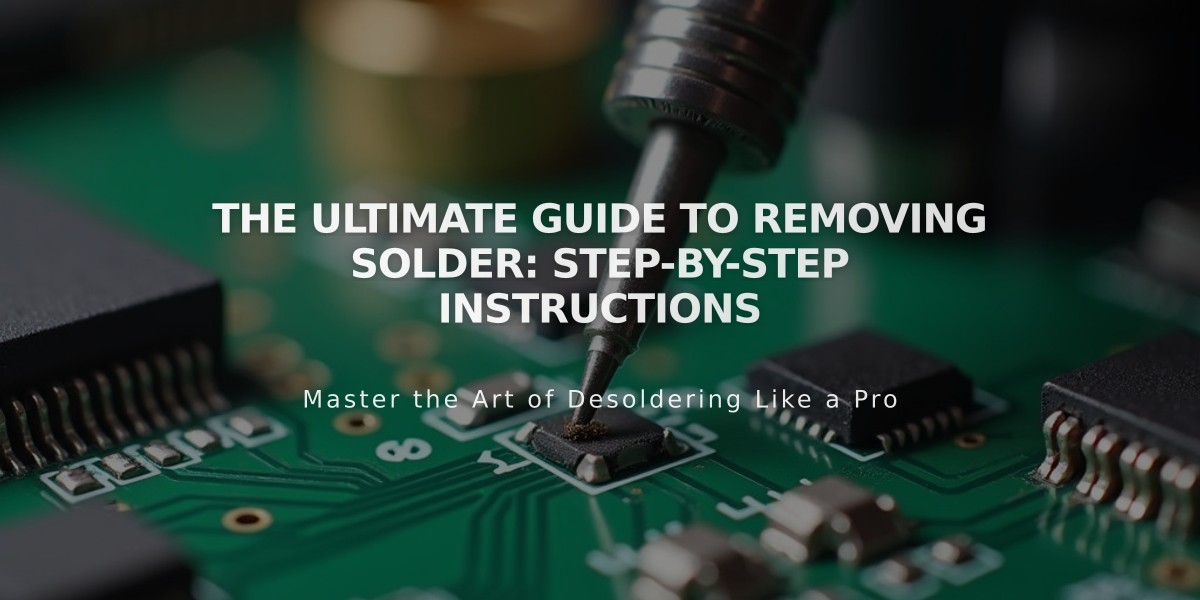

The Ultimate Guide to Removing Solder: Step-by-Step Instructions

Solder removal is a crucial skill in electronics work, essential for fixing circuits, replacing components, and maintaining electronic devices. Here's a comprehensive guide to help you master this important technique.

Essential Tools for Solder Removal

- Solder sucker (desoldering pump)

- Desoldering braid (copper wick)

- Soldering iron

- Heat gun (for larger components)

- Safety equipment (goggles, ventilation)

PCBasic logo on circuit board

Common Removal Techniques

- Using a Solder Sucker:

- Heat the solder joint with your soldering iron

- Position the solder sucker close to the melted solder

- Quick-release the plunger to vacuum up the molten solder

- Desoldering Braid Method:

- Place the braid over the solder joint

- Apply heat through the braid

- The braid will absorb the melted solder

- Move to a fresh section of braid as needed

- Heat Gun Technique (for larger areas):

- Apply even heat to the target area

- Remove components once solder melts

- Clean remaining residue with braid or sucker

Tips for Success

- Work in a well-ventilated area

- Keep your soldering iron tip clean

- Use appropriate temperature settings

- Don't rush the process

- Practice on scrap boards first

Common Applications

- Circuit board repair

- Component replacement

- Prototype development

- Electronics recycling

- PCB rework and modification

Best Practices

- Always wear safety equipment

- Maintain proper tool temperature

- Clean workspace after completion

- Inspect work thoroughly

- Allow components to cool before handling

With these techniques and proper tools, you can effectively remove solder in various electronics projects, from simple repairs to complex PCB modifications. Remember to prioritize safety and patience for the best results.